Design & Development

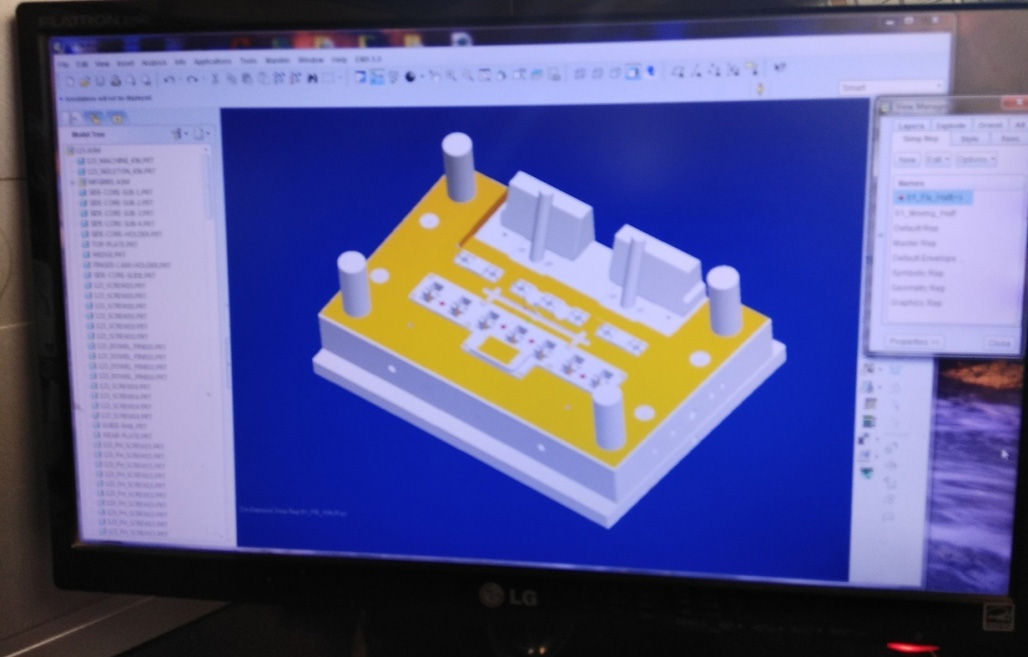

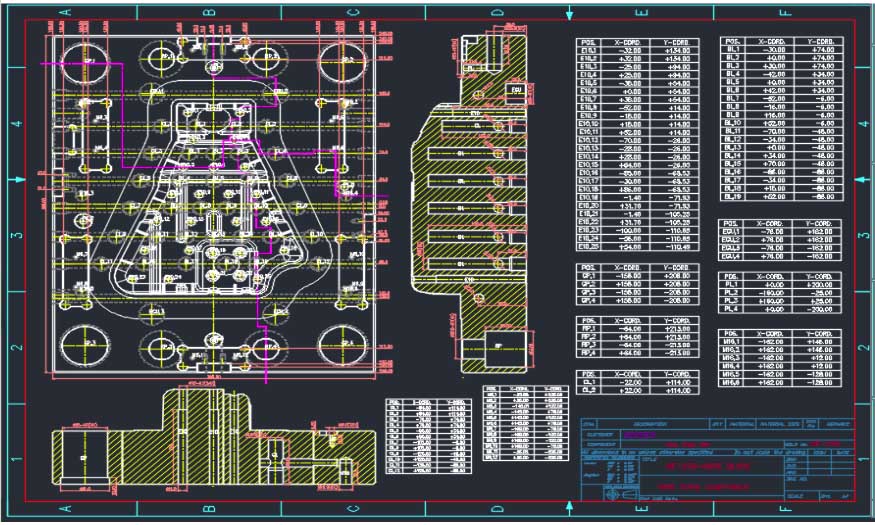

Our design team is capable of designing Progressive Stamping Dies; Injection mould; Jigs & Fixtures using the latest CAD/CAM software.

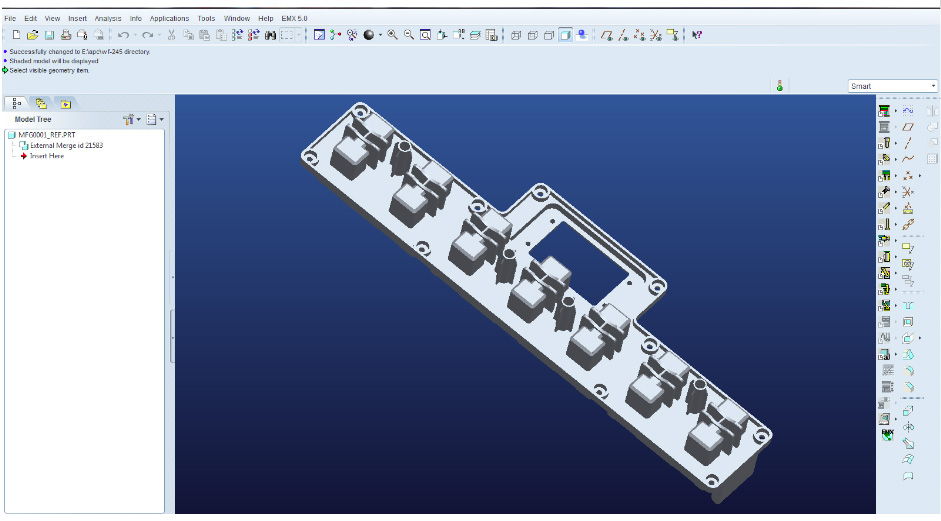

Wireform engineers are on the forefront of plastic piece part and injection mould design, development and manufacturing. Tapping into extensive experience and utilizing leading-edge software/technology, Wireform can help to design your plastic components from conceptualization and ensure that they are optimized for moulding. Wireform’s engineers can then design injection moulds, which are dependable, easy to maintain and interchangeable. If the design already exists, then Wireform review the design for productivity and build the mould per exacting specifications.

To facilitate paperless mould design and manufacturing, Wireform’s design engineers use PRO E and Iron CAD, a combination of two leading software solutions that enables Wireform to produce highly detailed computer-aided design and manufacturing (CAD-CAM) drawings. They use CNC (Computer Numeric Control) Wire and HSM (high-speed machining) equipment to build high-precision moulds to exacting tolerances. And they utilize Wire EDM (electrical discharge machining), Automated Sinker EDM, and small-hole EDM capabilities to facilitate production of mould cores and cavities with high degrees of repeatability and dimensional accuracy. EDM tools enable us to make accurate and repeatable high-precision cuts, handle comlicated draft angles, and inspect components inline.